Stainless steel is widely used in a variety of industries due to its durability, strength, and resistance to corrosion.

However, while it’s a durable material, it’s not immune to damage, particularly pitting¡which can make you wonder how safe using your stainless steel is.

Pitting is a type of corrosion that can occur in stainless steel when the protective layer on the surface is compromised.

It can cause small pits or holes to form on the surface, which can eventually lead to structural damage if left untreated.

However, pitting can be caused by a variety of factors, including exposure to harsh chemicals, high temperatures, and humidity.

With that said;

In this post, I will share with you what pitted stainless steel looks like, so you can recognize it and you will learn:

- What could cause pitting in stainless steel

- How you can get rid of them

Let’s go on.

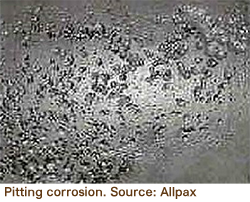

What does pitted stainless steel look like?

If you’re wondering what pitted stainless steel looks like, you’re not alone.

Pitting can be difficult to spot at first, but with a closer look, you can identify its telltale signs.

One of the most common signs of pitted stainless steel is small pits or holes on the surface of the metal.

These pits can vary in size and depth, ranging from tiny pinpricks to larger, more significant depressions.

They often appear as small, circular, or oval-shaped craters on the surface, and maybe more noticeable in areas where the stainless steel has been exposed to corrosive materials or high humidity.

One other common sign of pitted stainless steel is discolouration or staining on the surface of the metal.

This can cause the stainless steel to develop a reddish or brownish tinge, which can be particularly noticeable on polished or reflective surfaces.

This discolouration may be accompanied by rust, which can further compromise the integrity of the metal.

Asides from that, Stainless steel may also develop a rough or bumpy texture.

This can occur when the pits are deep enough to create unevenness on the surface of the metal, or when the metal has been subjected to aggressive cleaning methods.

Common Causes Of Pitting In Stainless Steel

Pitting in stainless steel can be caused by several factors, some of which are more common than others.

In this section, I will share some of the most common causes of pitting, and what you can do to prevent it.

One of the most common causes of pitting in stainless steel is exposure to harsh chemicals. Stainless steel is often used in environments where it may be exposed to chemicals such as acids, salts, and chlorides.

When these chemicals come into contact with the surface of the metal, they can react with the protective layer and create small pits or holes. This is especially true when the stainless steel is exposed to a combination of chemicals, or when it is exposed to high concentrations of these substances.

Pitting could also be caused by exposure to high temperatures.

When stainless steel is exposed to high temperatures like in the process of cooking, the protective layer on the surface of the metal can break down, leaving it vulnerable to corrosion.

This is especially true when the stainless steel is exposed to temperatures above its normal operating range.

Humidity is also a common cause of pitting in stainless steel.

With exposure to high humidity, the moisture can react with the surface of the metal and create small pits or holes.

This is especially true in environments where the stainless steel is not properly cleaned or maintained.

In addition to these common causes, pitting can also be caused by factors such as mechanical damage, improper cleaning methods, and exposure to high levels of UV radiation.

To prevent pitting in stainless steel, it’s important to take steps to protect the metal from these common causes.

This includes properly cleaning and maintaining the stainless steel, using protective coatings and barriers, and avoiding exposure to harsh chemicals and extreme temperatures whenever possible.

Can You Get Rid Of Pits In Stainless Steel?

If you’ve noticed pitting in your stainless steel products, you may be wondering if it’s possible to get rid of these small holes and depressions. While it’s not always possible to eliminate pitting, there are steps you can take to minimize its appearance and prevent further damage.

One of the most effective ways to minimize the appearance of pitting in stainless steel is to polish the surface of the metal.

Polishing can help smooth out the surface of the metal and reduce the visibility of pits and other imperfections.

This can be done using a variety of methods, including hand polishing, machine polishing, or chemical polishing.

However, it’s important to note that polishing will not eliminate pitting, and may only be effective for surface-level damage.

You could also fill in the pits with a filler material.

This can help smooth out the surface of the metal and create a more uniform appearance.

However, it’s important to use a filler material that is compatible with stainless steel and that will not cause further damage or corrosion.

In some cases, it may be necessary to replace the affected stainless steel components entirely.

This may be a solution if the pitting is severe or if it is affecting the structural integrity of the equipment or appliance.

Prevention is key when it comes to pitting in stainless steel.

By taking steps to protect your stainless steel products from common causes of pitting, such as exposure to harsh chemicals and extreme temperatures, you can help minimize the risk of damage and ensure the longevity and reliability of your equipment and appliances.

Conclusion

Pitting in stainless steel can be a serious concern, as it can lead to corrosion, structural damage, and decreased reliability of equipment and appliances. It’s important to be able to recognize what pitted stainless steel looks like, as well as the common causes of pitting, such as exposure to harsh chemicals and high temperatures.